7 Advantages of Barrel Plating

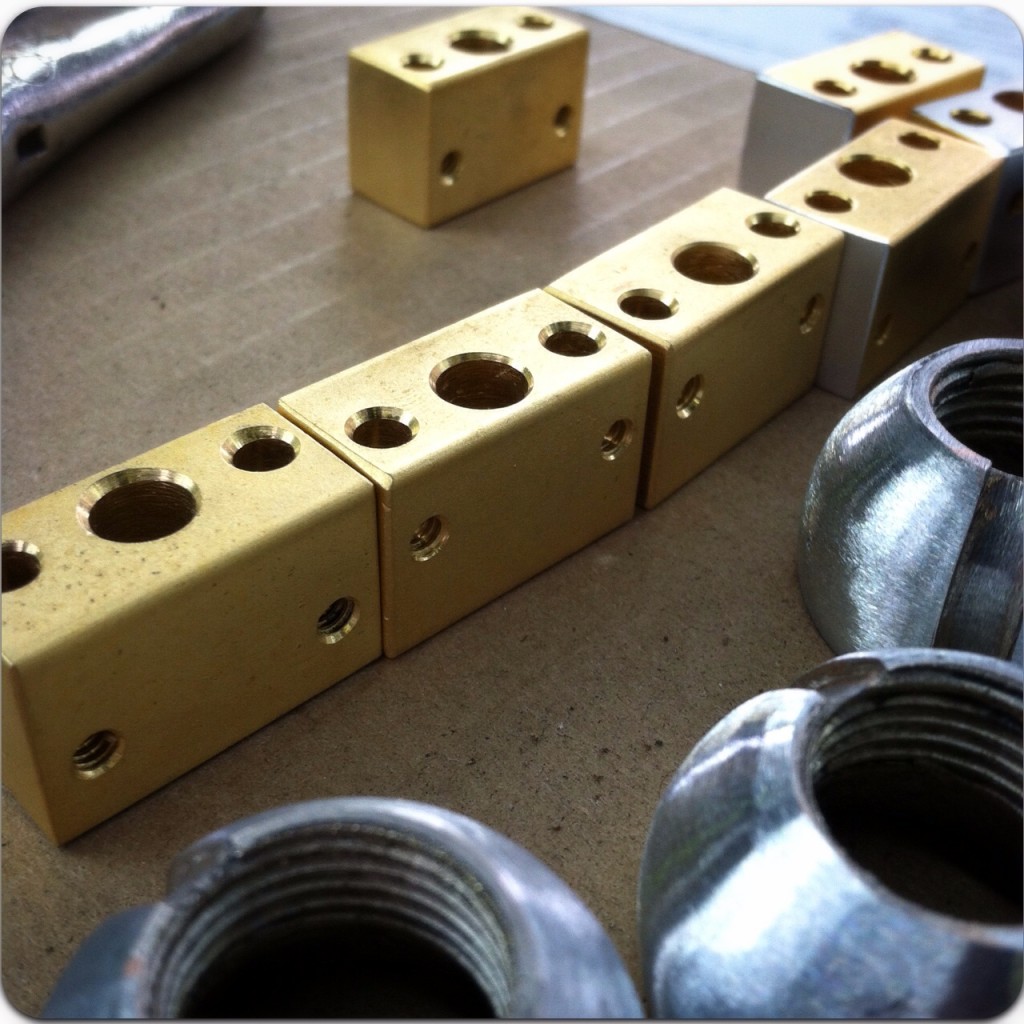

Barrel Plating

Barrel plating uses a rotating container that turns a large amount of items at one time as a result this is beneficial for mas production. The vessel is dipped in a number of different chemical tanks during the plating process. Metal ions in the electroplating solution attached themselves to the workloads surfaces hence plating the object.

Uses

1. Corrosion resistance therefore equipment last longer.

2. Decorative purposes hence adding a dazzling fresh shine on furniture.

3. Engineering finishes which as a result, protect from wear and tear.

History

During post-Civil War era, this coated equipment made from wooden barrels or kegs therefore more availability and lower costs. Today, equipment is made of non-conductive and chemically inert materials.

Advantages

In combination with higher levels of efficiency, there several other advantages to using the barrel plating method:

1. Large, rapid volume production in comparison to rack plating as a result is faster for production.

2. It requires less floor space and lower equipment investments as a result, saving businesses money.

3. Less labor is required compared to the rack plating process.

4. The entire plating process takes place inside of the barrel or vessel therefore only one person is needed per barrel.

5. Barrel plating is versatile: plating several objects at the same time is highly achievable.

6. The cascading motion produces a more uniformed metal finish in conclusion, the object has an even finish.

7. Agitation of the tanks solutions eliminate stratification and produces a homogeneous bath.

We offer both rack and barrel plating methods at American Plating Company, located in St. Louis , Missouri. For a price estimate call American Plating Company at (314) 776-0542 e-mail us through our Contact page.

Plating is available in gold, tin, silver, brass, nickel and copper.

References:

Singleton, Raymund. “Barrel Plating.” Metal Finishing 97.1 (1999): 346-67. Web. 26 July 2015.